What are the factors that affect the marking speed of Lanspeed laser marking machine?

What are the factors that affect the marking speed of Lanspeed laser marking machine?

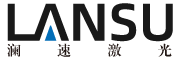

Laser marking machine is a kind of marking equipment with a high degree of automation. Not only the marking effect is clear and beautiful, the lines are clear and the marking speed is fast, which greatly improves the production efficiency of the enterprise, creates higher value for the enterprise, and obtains more In return, it is reasonable to be loved by the majority of users.

There are four factors that affect the marking speed of the laser marking machine:

1. Marking density: In the case of the same format, the same light spot and the same depth, the higher the marking density, the slower the corresponding marking speed, because the high density directly increases the marking area.

2. Marking range: The marking speed of a large range of laser marking machines is slower than that of a small range, because the deflection area of a large range of marking galvanometers will naturally increase the speed of the marking. influences.

3. Marking depth: According to requirements, if you need to deepen the marking depth, you need to adjust the parameters of the fiber laser marking machine and increase the power and current parameters of the fiber laser marking machine, which will affect the marking speed.

4. Laser spot size: The smaller the spot size, the smaller the marking volume. Therefore, the larger the spot size, the faster the marking speed.

I will share with you the four basic methods of laser marking machine filling

1, two-way filling: marking efficiency, the effect is good.

2. Backfilling: It is only used when marking thin graphics and fonts, and its efficiency is similar to bow filling.

3. Unidirectional filling: The marking efficiency is slow, and it is rarely used in actual processing.

4. Bow-shaped filling: Marking efficiency is relatively high, sometimes there will be problems of connection, unevenness, etc. When marking fine graphics and fonts, the above problems will not occur, so bow-shaped filling is preferred.

The above are the four basic filling methods of the laser marking machine. Choosing the right way to work can do more with less!