- Fiber laser marking >

- 20W fiber laser marking machine

- 30W Fiber Laser marking machine

- 50W Fiber Laser marking machine

- Ultraviolet laser marking >

- 3W UV Laser Marking machine

- 5W UV Laser Marking machine

- 10W UV Laser Marking machine

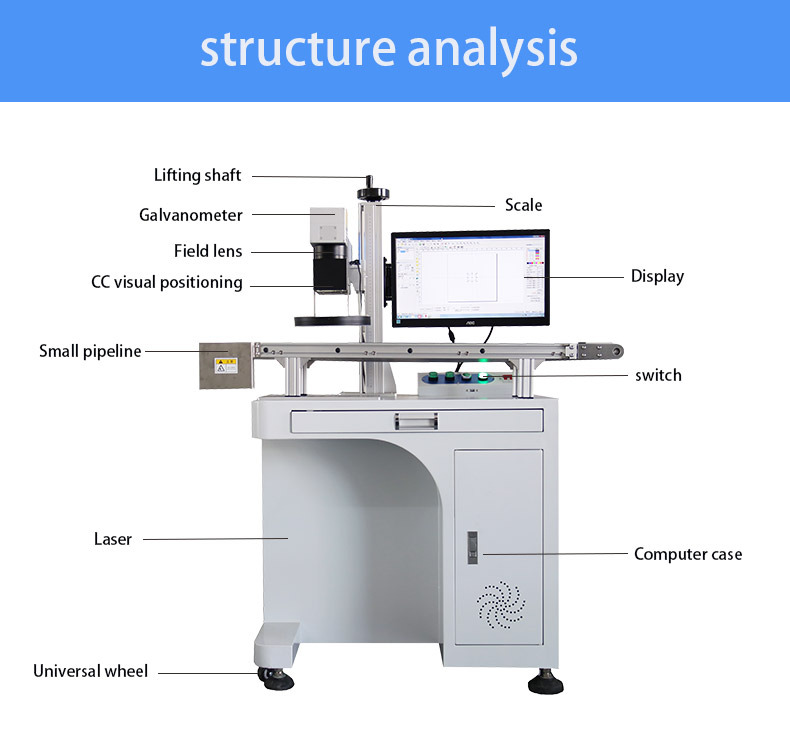

CCD Visual positioning laser marking machine Descrption

CCD vision positioning laser marking machine is mainly aimed at the problems of difficult feeding, poor positioning and slow speed caused by the difficulty of fixture design and manufacturing in batch irregular marking. Way to resolve. The system provides random feeding, accurate positioning and marking, which greatly improves the marking efficiency.

Applicable industry

It is suitable for occasions with large workload, difficult positioning of feeding, diversity and complexity of workpieces.

Camera system

Single CCD camera positioning system

Dual CCD camera positioning system

Coaxial CCD camera positioning system

Introduction of CD camera system

1.3 million and 5 million camera pixels (optional)

Camera response time 200 ms

Camera accuracy 5μ

Camera marking method: archive the workpiece surface to be lasered